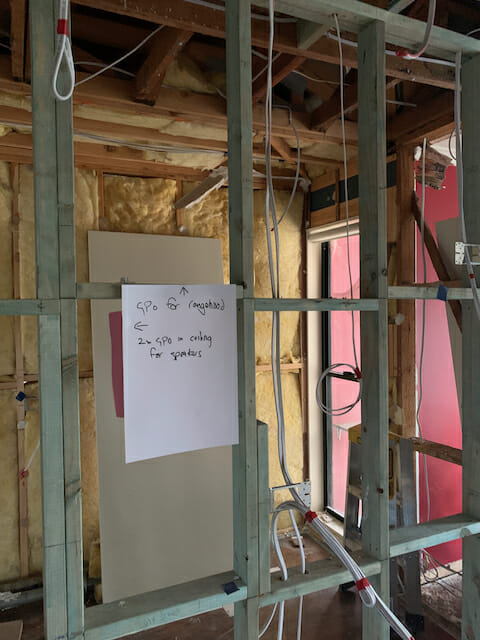

A big day today. The build encroached into our living space today. The main part of the renovation is now ready for sheeting, so it is time to get to all of the other jobs we’ve planned. In our living space we are removing old joinery and streamlining the design to give us more space and recovering the floor. Twenty years of wear and tear, cats and a dog has certainly left its mark.

It feels as if we are being squeezed out of our house. All we have now is our bedroom and the makeshift office. When I said on day one we are performing open heart surgery on our house, well now that has grown to a heart and lung transplant as well. Whereas we can see the future benefit, living through it is difficult. Our living space, TV, music etc, has been demolished. We now have a ramshackle collection of cables and a TV balanced on an old blanket box. The cat zone if devoid of any comfortable space for our cats and our poor dog doesn’t know which way is up.

As the team demolish the joinery they come across a time capsule of sorts. They give it to me and I open the little carboard cylinder. Inside is a die cast metal racing car, Dick Johnson’s number 17 GreensTuf Falcon from the 1983 Bathurst 1000. It is the one he smashed at the Forrest Elbow on top of the mountain winding up in the scrub during qualifying. I was, still am, a big fan of the DJR racing team. Ironically, this weekend coming will see the race run with almost no crowd as we all continue to manage through the COVID pandemic. Wow, 37 years since the event and some 18 years since I hid the little model away. It now sits on my desk as a reminder of how quickly time passes and how, in the blink of an eye, life can change.

The boys get back to work as this manic day continues. Mardi and I get back to the office to do our work.

The certifier arrives to certify the work prior to sheeting, the Gyprock sheets arrive, demolition continues, Chris, our builder, has his kids with him and they are fascinated with our pond and gold fish, every door in the house is open and we have cats and a dog all over the place. It’s a mental day.

As the house slowly becomes quiet as people leave and we finish up work for the day we go back to our living room and take in what looks a little like a disaster zone. Our cats slowly emerge and inspect their changed surroundings. Cast are amazing, you only have to move one piece of furniture and it’s like, wow, you’ve renovated, let me look around and check it all out. It’s a bit like that, our cats walking around inspecting everything. They haven’t seen the new area yet, it’s been blocked off for weeks. That’ll be an adventure.

We settle down and relax for a while.